A couple of years into working in the construction industry after graduating with an Architectural Master’s degree in 2016, Neal Vella, founder of bespoke and hand-crafted products brand Form Matters, discovered a love for furniture and product design, with a special interest in the manufacturing processes that go into production.

It could be said, however, that his passion for craftsmanship was sparked at an early age. “Growing up in my father’s carpentry workshop, I was exposed to a hands-on approach to problem-solving. My time spent at the workshop alongside my father instilled in me a love for manufacturing and raw materials, which at the time consisted mainly of woodwork,” says Neal.

This, coupled with a fascination for how a piece of wood could be transformed into an object “that has a purpose, aesthetic and most importantly, that fulfils a function,” as well as his exposure to the work of different designers and architects from his studies, allowed Neal to learn many aspects of design; “from the importance of detailing to different material properties; from purely aesthetic conceptual work to functional and practical objectives,” he explains.

The turning point that led Neal to switch gears from working as an architect to starting his own business as a product designer happened around the time that he, along with his wife, began working on their home, which posed several design challenges and opportunities of its own.

The house required a spiral staircase to connect different spaces within it. My wife challenged me to design the staircase and build it from scratch. Admittedly, this was no mean feat, but a crucial point of encouragement was when my wife bought me a CNC machine,” says Neal, which is used to cut a variety of materials, including wood and steel. “Upon receiving positive feedback from my friends and family, and the personal satisfaction I got from the design and manufacturing process of the project, I knew that product design was the career I wanted to pursue.”

This satisfaction served as the basis for Neal’s brand Form Matters, the primary idea behind which was to launch “a consistent brand that focuses on beautifully crafted pieces, which are functional and made to last.” This evolved into the production of exclusive, limited-edition collections, a concept, as he puts it, “that goes against today’s ideology and demand for mass production. Ultimately, I would say that Form Matters can be summed up in five words: sophisticated, distinct, personal, hand-crafted and experimental.”

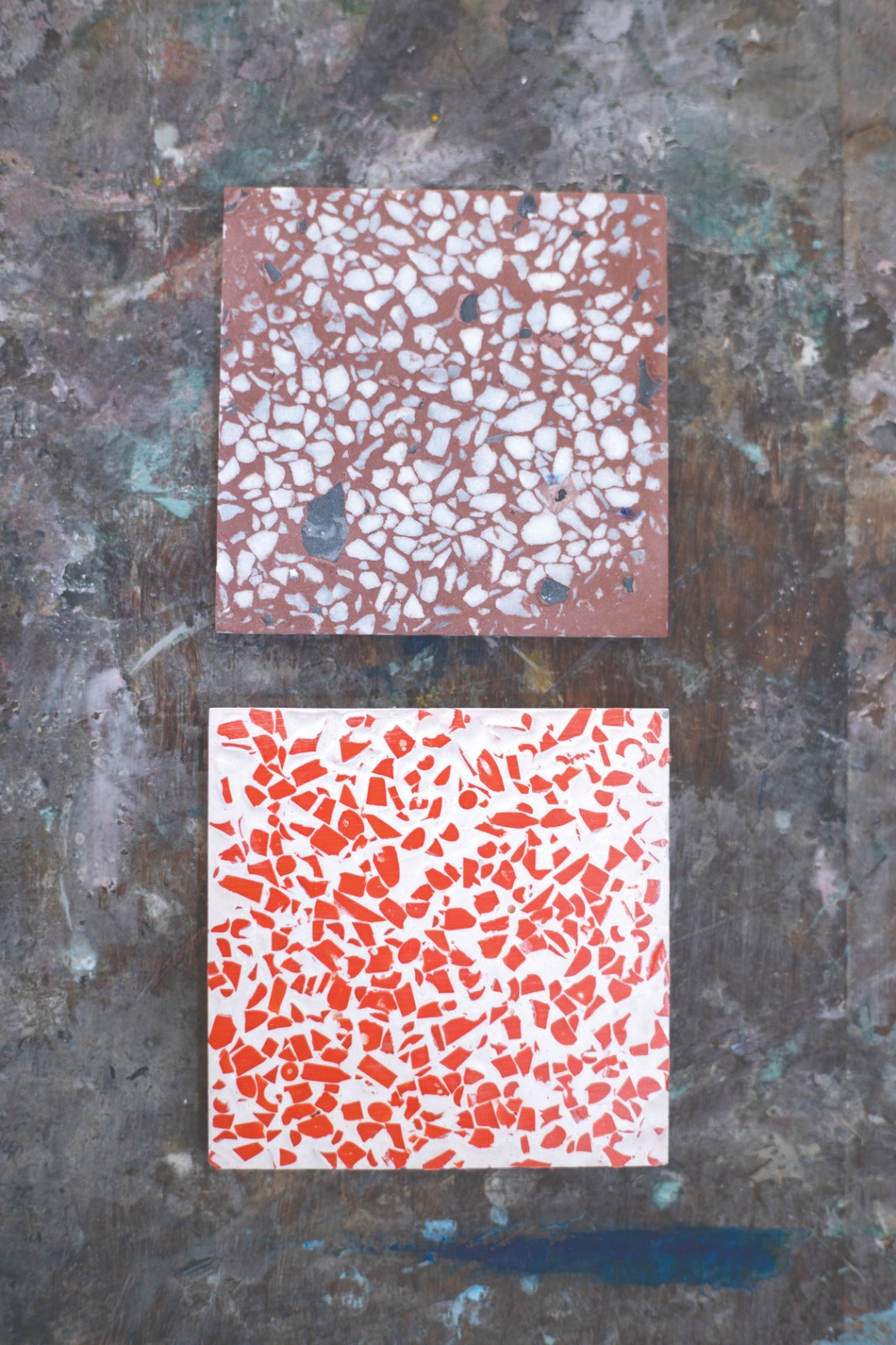

From bespoke side-tables to coasters and kitchenware, a material favoured by the designer is terrazzo, which he describes as extremely versatile and that can be combined with other materials such as wood, marble and recycled plastic to create distinct finish colours and material combinations.

“It is also easily recyclable, allowing us to adopt a sustainable approach to our manufacturing process. Further to this, authenticity lies at the heart of terrazzo making. Every colour and chip combination is unique and almost impossible to recreate precisely. The process is fun, especially since we are not in control of how the chips fall into the mould, making every product individual.”

There are, however, challenges that arise from working with terrazzo. Neal says it is a brittle material, “and even though it can take the shape of practically anything you cast it into, the form dictates the structural integrity of the object. Moreover, it is a very porous material – this brings about some challenges when we use it to create kitchenware objects for our collection.”

Describing the creative process behind the products designed by Form Matters, Neal says that everything is designed in-house by a small creative team – from the initial sketches to the final product. “Our production process is a collaborative effort with the single aim of creating products that are well made and made to last,” he explains. “Further to this, our designs are characterised by functionality. We experiment with how things are constructed, developing new details and techniques for bringing different materials together in their simplest form.

The design phase begins with ample brainstorming, bouncing of ideas, criticism, sketching and prototyping, which allow the team to analyse and understand the product’s potential function, manufacturing issues, and aesthetic. Their go-to material for prototyping is wood due to its versatility and widespread local availability.

“When we’re pleased with the final prototype, we move onto the mould-making process to create reproductions. We experiment a lot with colours and other mixture additives such as marble, glass or recycled plastics, to create different finishes and textures,” says Neal. “Once the finish is decided, we then start producing several limited and exclusive runs from each design.”

Sharing the design which has proven to be the trickiest to produce so far, Neal says that, while all product designs pose their own challenges, the cross tops the list. “The biggest challenge was to achieve the desired form with the smallest thickness of material possible, to be able to easily remove the product with care from the mould without breaking it.”

Recently, the team has also started exploring and experimenting with a unique vase-making process – a product they will be launching soon. “In such a production process, we use sacrificial moulds. To make each product, one has to achieve the perfect balance between the viscosity of the mixture, the ratio of chips to base material, the thickness of the surface and the evenness of the material on the mould,” Neal explains. “The ultimate challenge of vase-making is that all of this has to be achieved in a relatively short period of time before the mixture hardens. Messing up any of these crucial aspects of production is a recipe for disaster.”

Going forward, the aim of the team is to continue building its terrazzo collection by introducing new products and exploring different materials, such as ceramics and recycled plastics, always backed by the aim of promoting local contemporary design, “integrated with traditional craftsmanship such as carpentry and metalwork and the modern processes of manufacturing to challenge the boundaries of conventional design.”

The founder adds that, being an environmentally conscious brand, the next step is to introduce a new range of products that integrates reused and recycled materials as part of its manufacturing process. “This is one of the main reasons we use terrazzo, since the majority of the material produced can be reused at any stage of the production process.”

Sharing some personal highlights since launching Form Matters in 2018, Neal asserts that among the most rewarding ones from the past year was turning his business “from a hobbyist Facebook page into a brand, promoting local hand-made design and manufacturing”, followed by the launch of the Terrazzo Collection. “We have also been privileged enough to be approached by a number of potential foreign clients to export our products abroad. This notion does not only appeal to us, but it also motivates us to grow our small business further and to introduce our locally made products to the foreign market.”

While challenges, naturally, have also surfaced – Neal singles out the design of the wall clock as the team’s ultimate challenge – he is driven to continue delivering brand consistency, “sticking to our core values and visual identity as the ultimate guide for anything we release to our customers. Lastly and most importantly, we intend to keep on challenging our current work ethic, to explore new methods of manufacturing as we strive to improve upon our work.”

This interview was first carried in Business Now magazine, the sister brand to BusinessNow.mt

Malta’s next leap: Secured

How ESET delivers enterprise-grade security to meet Malta’s digital ambitions

Mastering the language of business: How BELS is crafting bespoke training for a dynamic economy

BELS Malta Director of Studies Arianna Muscat on how the language school helps companies equip their teams for success.

Built differently – CLA Malta offers custom solutions in a cookie-cutter landscape of tax advisory and business

Their client-centric philosophy extends far beyond conventional consultancy.